|

As some of you may know I am a die hard scratch builder, my claim to fame being my "Lead Sled" chassis from the first

Proxy race held several years ago by Bob Ward on the West coast.... Where I was soundly beaten by Russell Sheldon :-)))

Well, over the last few weeks I have been giving different chassis materials a look see. I have been working on

my Euro-cars to get them to run better on my routed track and after having success with a Ninco BMW V12 project car. I decided

to check some of the other building materials out... I was looking for a nice light material that would work well on

both wood and my Ninco track. A little lead on the chassis for the wood track and a magnet to help with the handling on the

Ninco track... Sounds good to me, now lets see if it will

work :-))

I made up several styrene chassis and they were okay, but lacked the stiffness I was looking for. I had to put styrene

runners down the length of the chassis to keep them from flexing, causing a serious wheel hop problem..

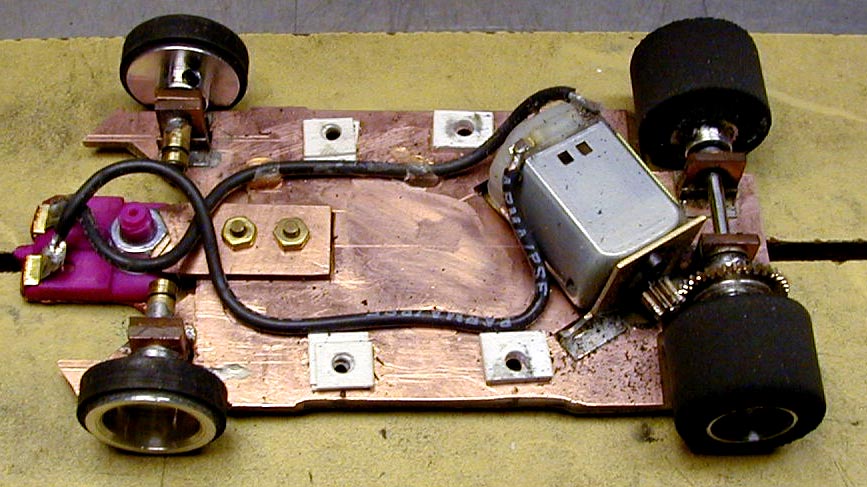

So I tried some Printed Circuit Board ( PC Board ) ... I had seen a chassis that was made from the PC board on one of

the DL's, so I thought I would give it a try.. The first thing that I found was that it was much stiffer than styrene and

didn't need any runners to strengthen the main pan... You should be able to find the PC board at most electronic stores, I

got mine from Radio Shack...

The board is easy to work with and is a snap to cut with a Dremel tool, and can be shaped with no problems with a file

or a sanding block..

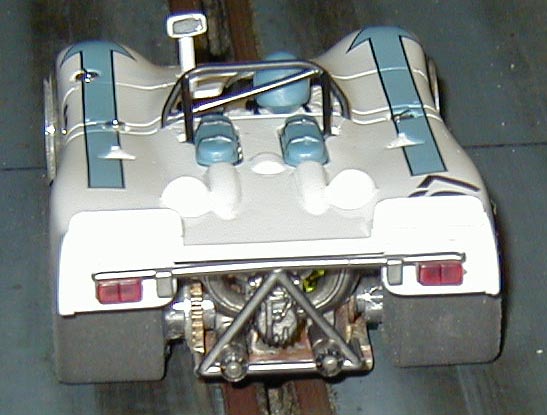

I decided to go with a anglewinder set up on my first try... With this set up I could keep the full interior and rear

end detail of the Porsche 908 I was going to try the chassis under..

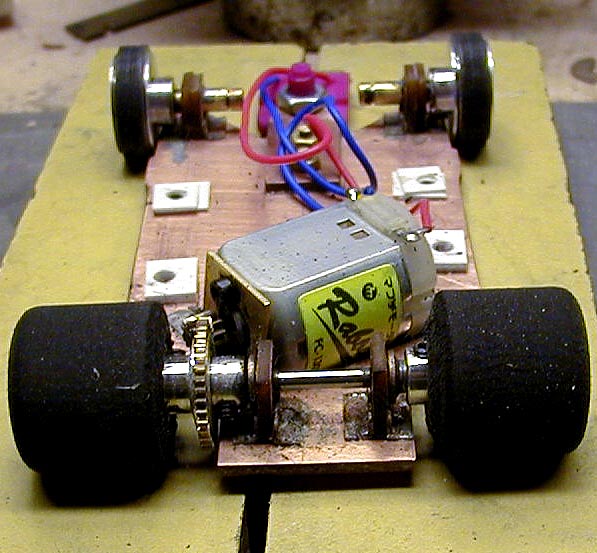

The chassis is a fairly simple pan design.. I used pillow blocks for the front and rear axle carriers, the pillow blocks

are also made from the PC board.. Along with the guide tongue.... The motor bracket is from Champion

There are a couple of things that I learned about working with the PC board material... The first is that you don't want

to over heat the board when you are soldering your parts to it :-))

On my first attempt at doing up the chassis I had cut out the pan and made the slots for the pillow blocks.. On

a regular brass chassis all you have to do is set the pillow blocks and then heat it and let the solder flow into the slot

to the joint... But on the PC board that wont work..

So I found some L channel brass and cut that to size to use as supports of the pillow blocks... Got the pillow blocks

and the L channel parts in place and grabbed my trusty torch which I have used to solder all my chassis with for years. And

thought I will just give it a quick shot of heat to get the parts soldered and... BAD IDEA.... under high heat the copper

film on the PC board will delimitate in short order :-))))

After starting all over I found that a 30 watt soldering iron will get the job done.

But you first need to "tin" all

the parts to be soldered... Then you can put the parts into place and then solder them together with the iron.. For my solder

I used a very fine wire silver solder that I also got at Radio Shack...

I used this method on all my chassis parts except for the guide tongue.. As you see I had to bolt that to the chassis...

I couldn't find any easy was to solder the tongue to the chassis...

The motor bracket was done in much the same way as the pillow blocks but with a slight twist..

For the motor bracket

I had to have something on the edge of the PC board to solder the motor bracket too... So I turned the L channel around so

that it now sits on the chassis and also covers the inner edge of the cut out for the motor bracket..

If you look close you can see one of the sections that hold the motor bracket to the chassis... With the channel parts

soldered in place I then soldered in the Champion motor bracket....

With the chassis done I added my running gear... For this chassis I picked a Pla-Fit Rabbit motor, 3/32 axle for the

rear, 1/8" stub axles for my front independent wheel system, Sonic 64 pitch gears, Parma tuna rear tires and American line

1075 front wheels... Then mounted the 908 body using a 4 point mounting system to allow the body to float on the chassis..

.

So how did it the whole thing turn out you ask ??? I am happy to report that the chassis is a great runner......

I had to add a bit of weight to the bottom of the chassis, but the whole car ended up only weighing in at 106 grams (3.8

oz) and that is with the lead weight added to the chassis... As a comparison the Ninco BMW V12 with about the same lead added

to the chassis weighs in at 114 grams (4.0 oz)

The car is a dream to drive.... Just as smooth as any of my brass scratch built chassis cars... And almost as fast...

My brass chassis anglewinder run in the 5.3 to 5.5 second range... Even with the weaker Rabbit motor in the 908 it is running

a consistent 5.6 second range....

So for you guys that are thinking of trying your hand at a plastic chassis... Give some thought to using PC board as

your building material.... Just as cheap to buy, stronger, stiffer and just as light as styrene... Give it a try you'll

like it :-)))

|