|

I have been asked several

times to describe how I mount my hard plastic bodies. So it is time to go over how I like to mount them.

For my cars I like to use

4 side mounted brackets that allow the body to float on the chassis. This helps to isolate the body from the chassis and allow

the car to run smoother and handle better.

The first thing to do is

set the body on the finished chassis and set the wheel well clearance for the front and rear tires… This lets me see

how the body will end up sitting on the chassis and how well it looks.

|

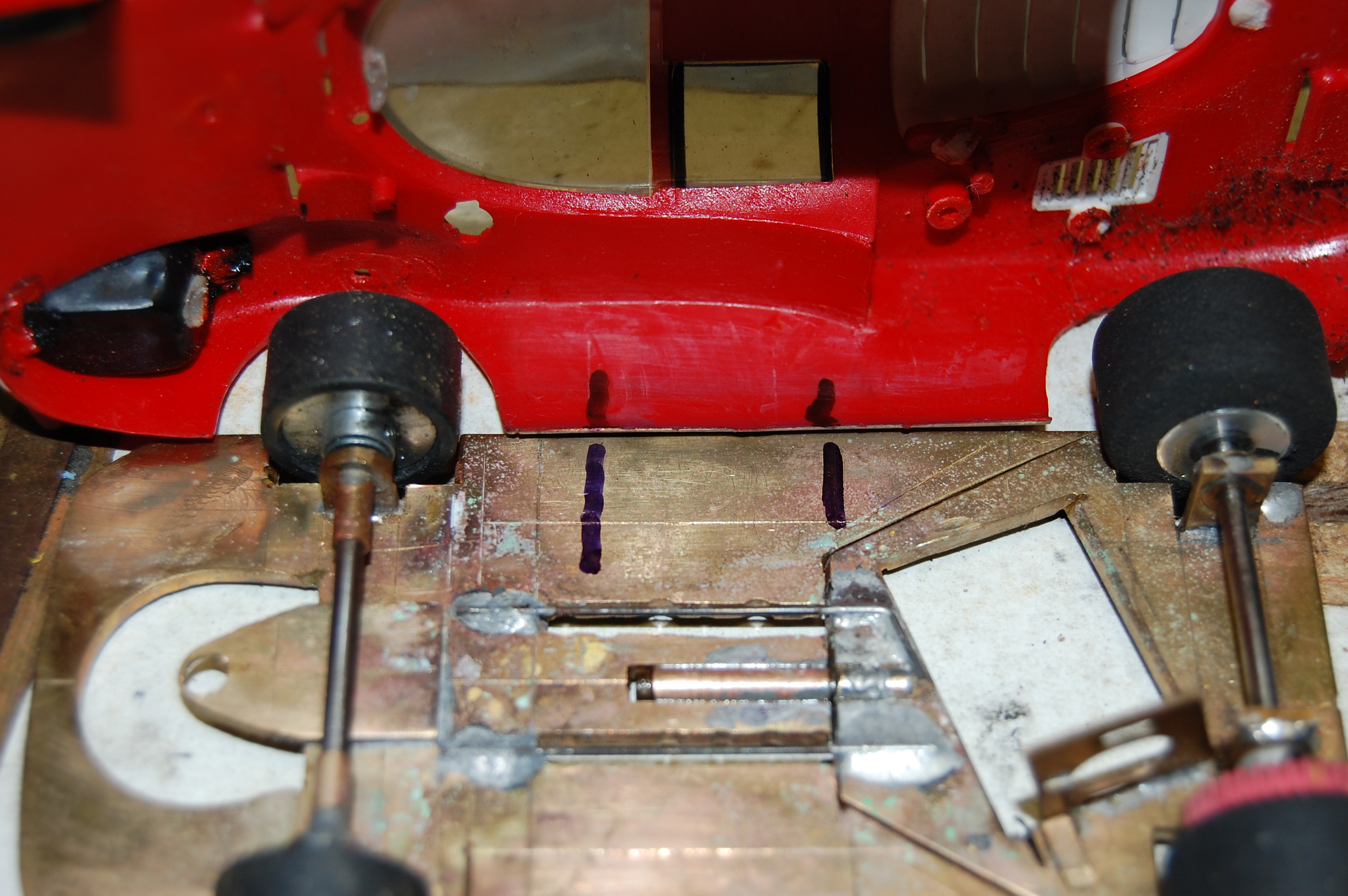

| you can see the rear rod sticking out on top of the rear wheels |

On this

Ferrari I used a .055 rod set over the center of the rear wheels. And on most cars I use the same size rod on the front too.

But with the Ferrari there are two duck vents that raise the front up too much, so I used some brass sheet stock to fit under

nose of the car as a shim to lift the nose to the right height.

You can

use any size rod you want, I normally use anywhere from a .047 to .062 dia. Rod to set my wheel well clearance to the look

that I like..

Now you

need to locate where you want your mounting brackets to go.. Try to give yourself

about a half inch or room between the brackets outer edge and the wheel wells.. You’ll see why later.

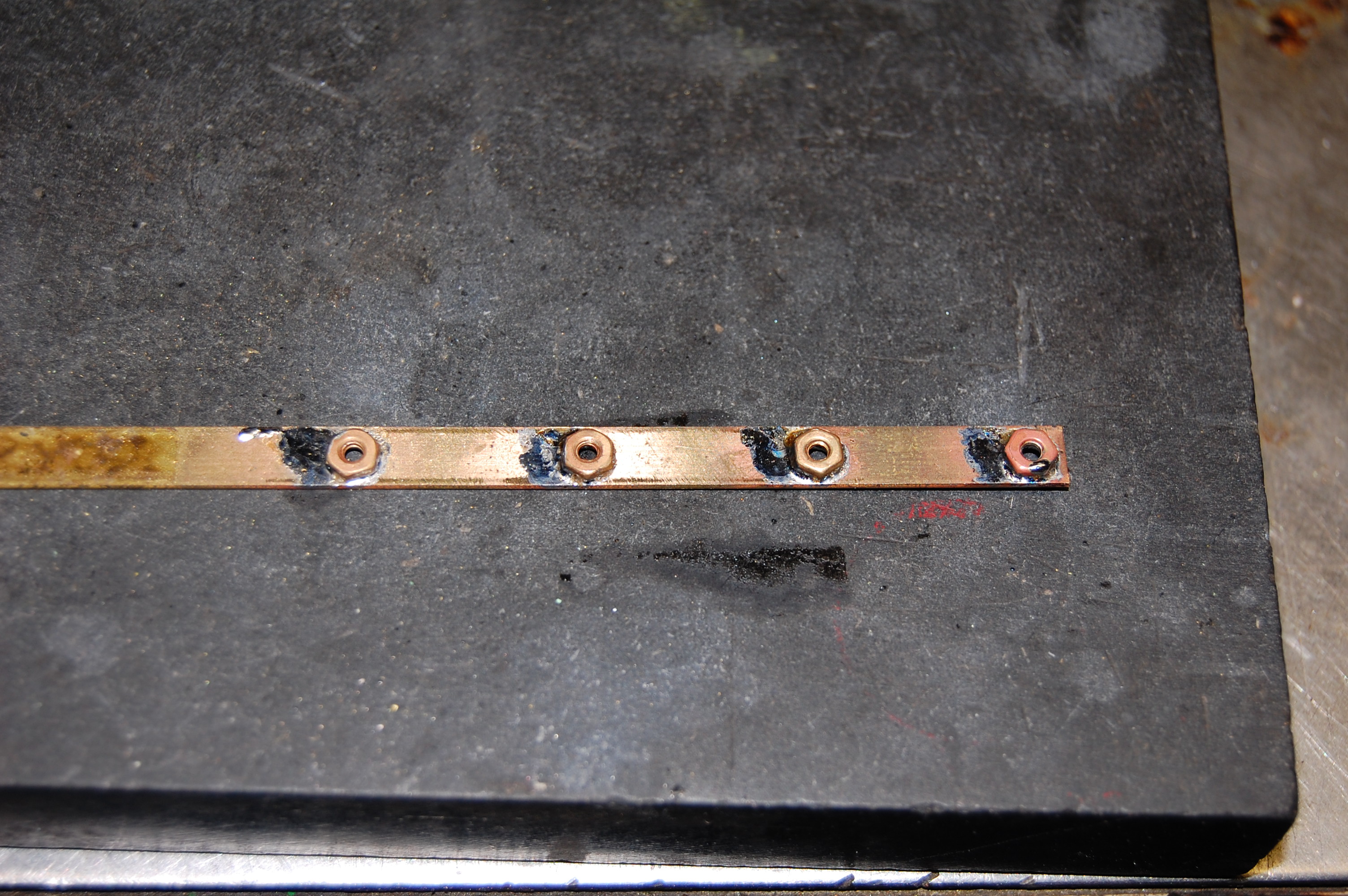

Now it’s

time to make up the brackets. I use a ¼” wide strip of .032 brass, And drill a 1/8” hole and space them 1 ¼’

apart.

For the

nuts I like to use 2-56 brass nuts and flat head screws. I have found that the 4-40 nuts are just too big for the space I

have to work with.

Now solder

the nuts to the brass strip.. And it is a good idea to have a 2-56 tap on hand. As a rule not matter how careful you are you

will get solder in the threads and the tap will clean it right out.

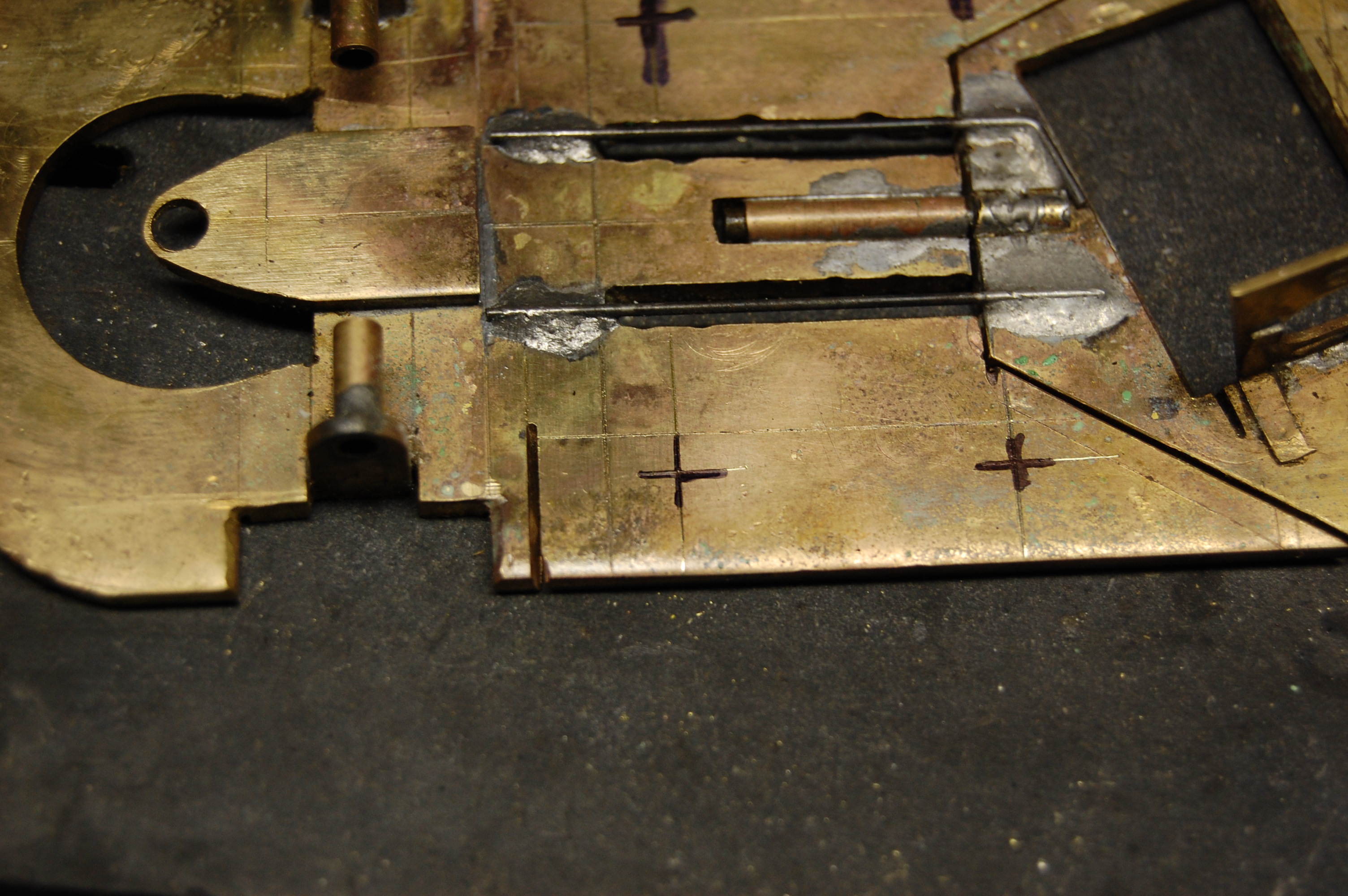

Now mark your chassis for

where your 3/32 drill holes will be. And mark them in ¼” from the outer edge of the chassis.. The 3/32 holes will give the screws room to move and allow the body to float on the chassis when you back

them out ½ a turn..

Body Mounting Part 2

|